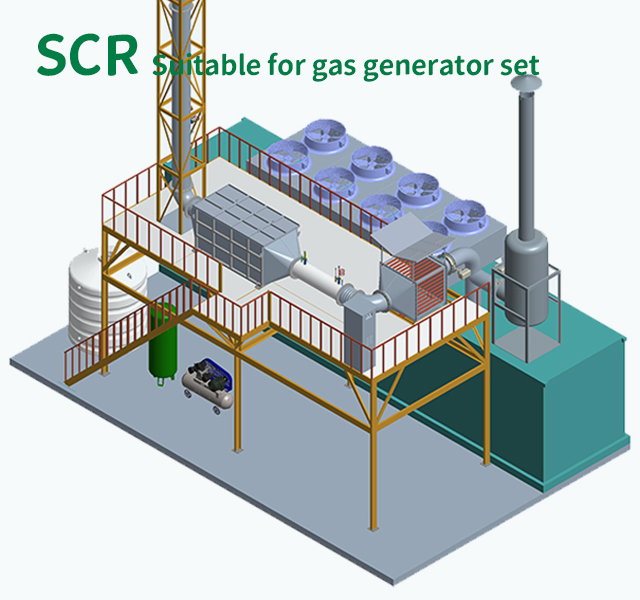

L-GETX Series SCR System

Model number:L-GETX

Leelool SCR system adopts selective catalytic reduction (SCR) technology, has the characteristics of low operating cost, convenient installation, safe operation, and online real-time monitoring.

▍Product Introduction

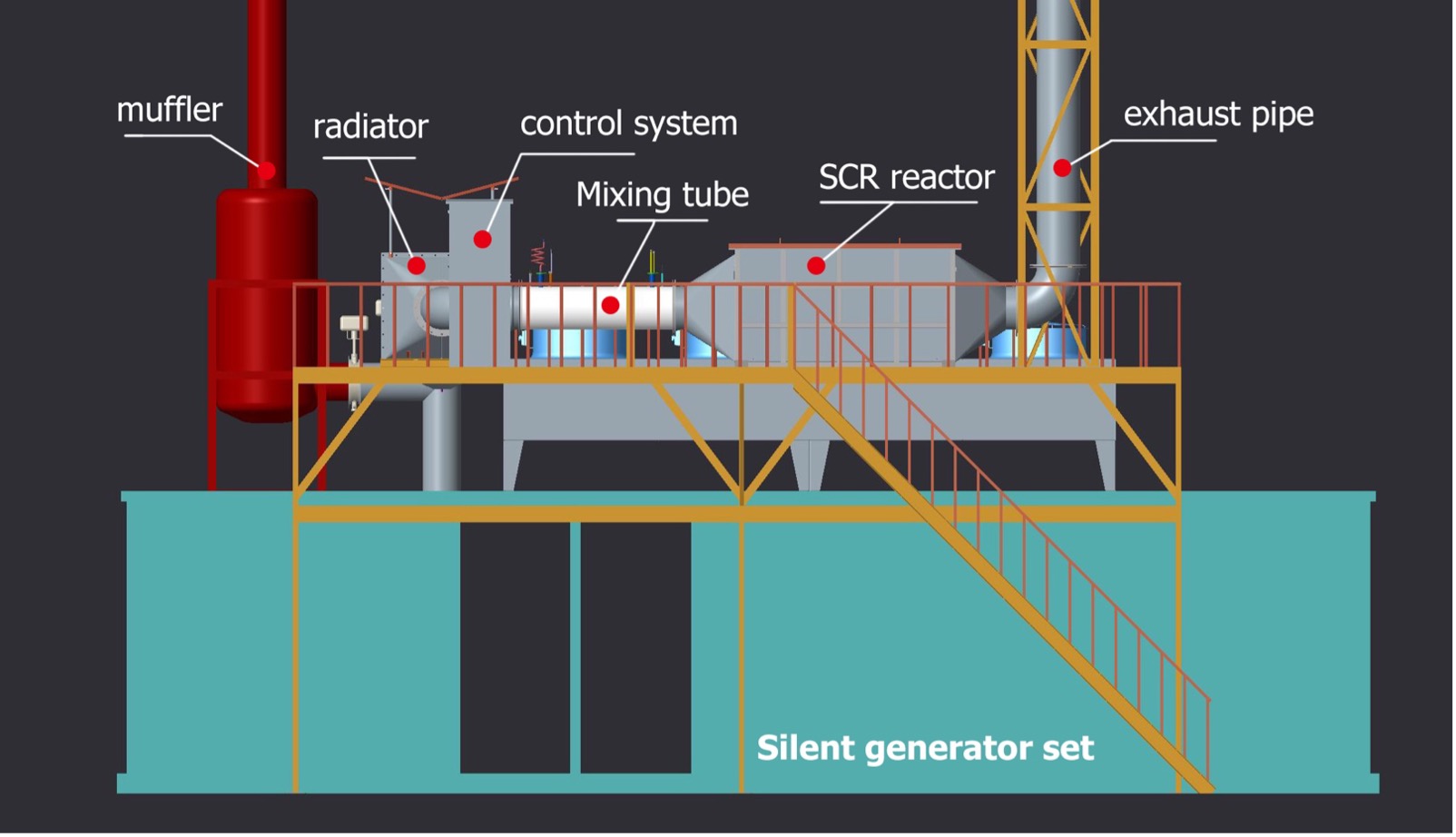

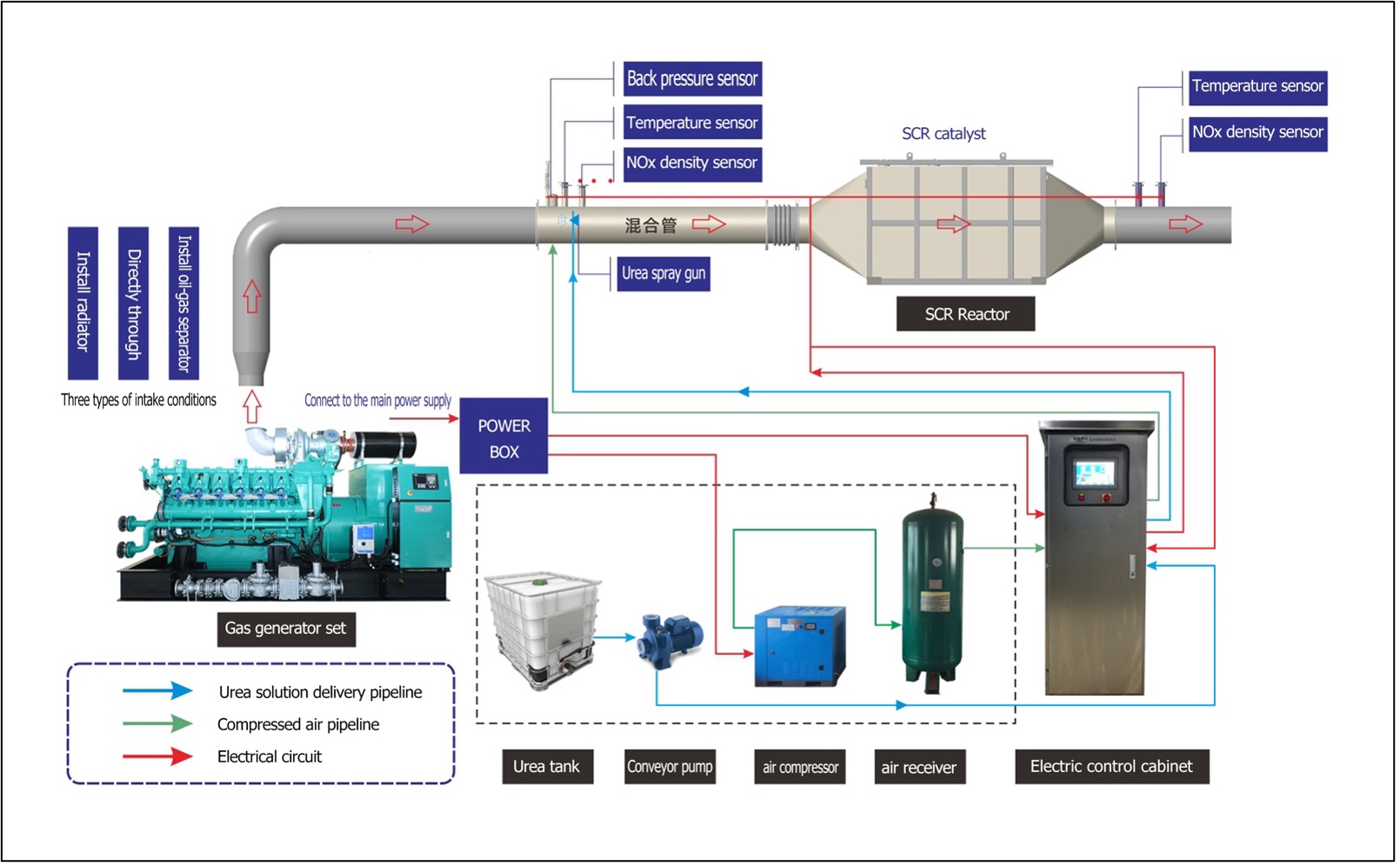

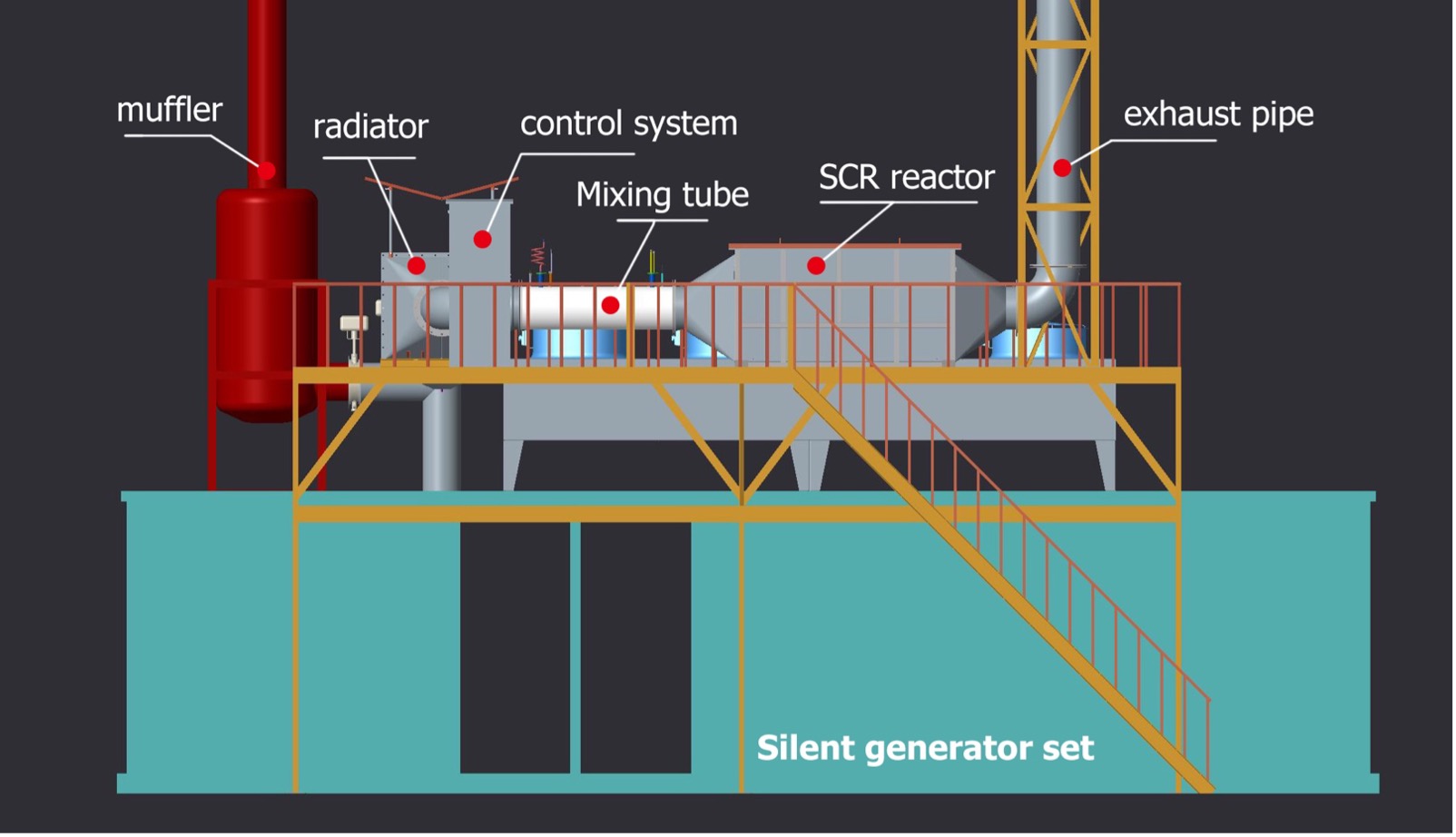

Leelool L-DETX/L-GETX series diesel/gas engine exhaust denitrification system consists of a mixing pipe,control system,SCR reactor,gas storage tank,air compressor,injection system,and urea tank.Adopting selective catalytic reduction(SCR)method.According to the engine exhaust temperature,it is possible to choose to install a radiator or heater to ensure that the exhaust temperature entering the SCR denitrification system is within the active temperature range of the SCR catalyst,thereby effectively treating nitrogen oxides NOx in diesel/gas engine exhaust.Leelool SCR denitration system has the characteristics of low operating cost,convenient installation,safe operation,and online real-time monitoring.With years of research and practical experience,it has gained the trust and witness of many industry users.

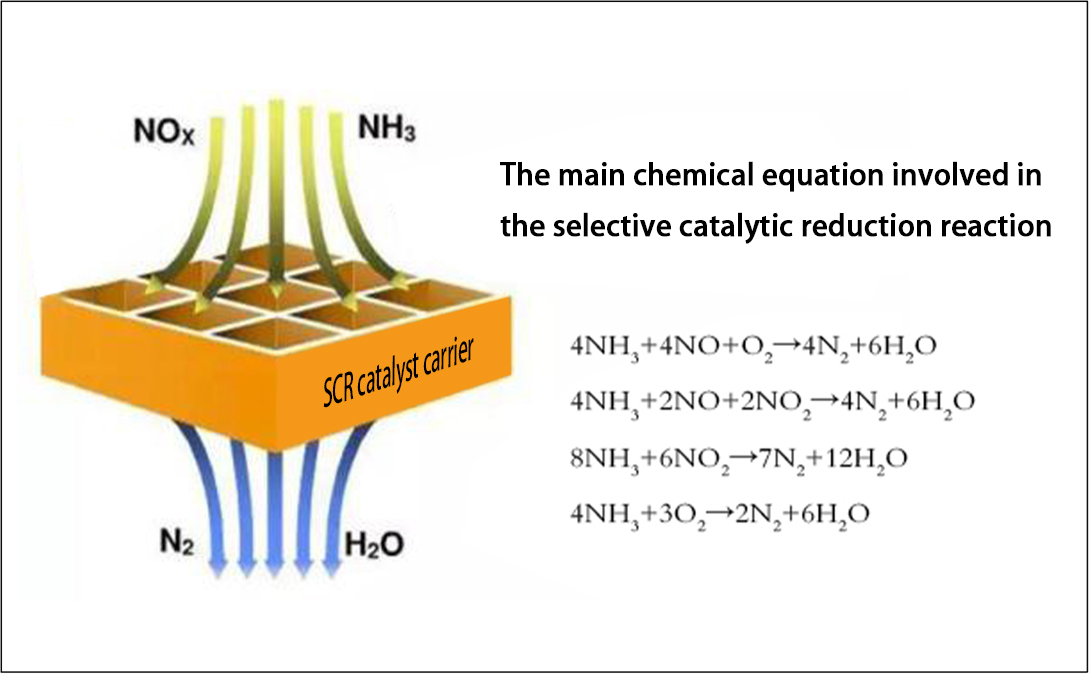

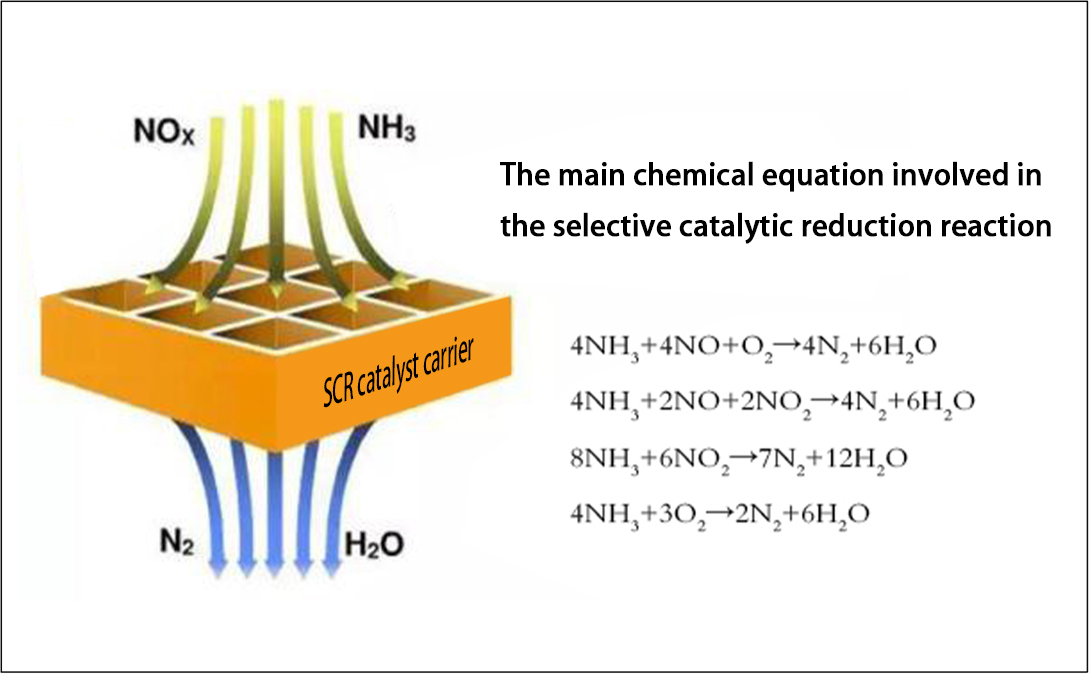

▍Introduction to SCR Technology

Selective Catalytic Reduction (SCR) method uses ammonia gas or a 32.5% urea solution as a reducing substance to control the concentration of nitrogen oxides in diesel engine exhaust. Under conditions where the oxygen concentration is more than two orders of magnitude higher than the nitrogen oxide concentration, under certain temperature and catalytic action, ammonia is used to reduce nitrogen oxides to nitrogen gas and water vapor. Since ammonia preferentially reduces nitrogen oxides and does not react with oxygen, it is called "selective catalytic reduction". For excess ammonia, a certain proportion of ammonia escape catalyst (ASC) can be coated at the end of the SCR reactor to ensure that ammonia reacts with oxygen to generate nitrogen and water vapor, avoiding secondary pollution caused by ammonia leakage.

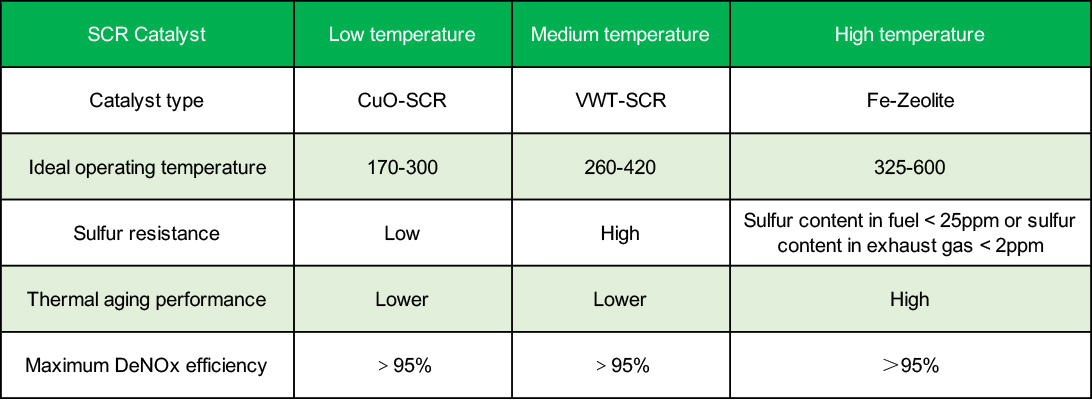

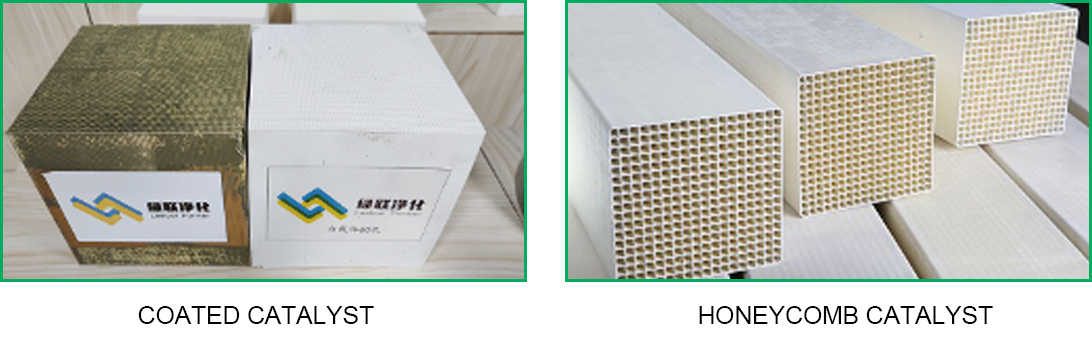

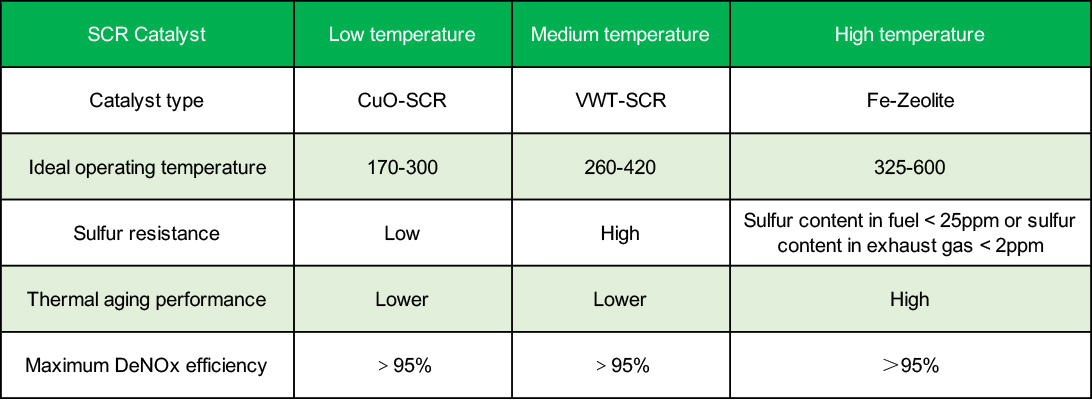

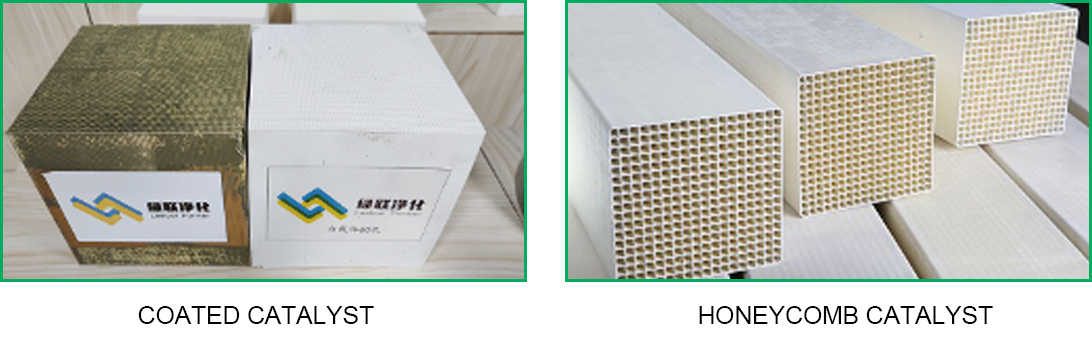

▍SCR Catalyst

▍Product Features

Custom Development: The Leelool database aggregates the raw emission data of globally leading high-horsepower engines. Concurrently, the company has delivered successful emission control solutions for PM, CO, and NOx pollutants across dozens of 1MW+ engines—spanning multiple fuel types and operational scenarios—for renowned manufacturers including Jenbacher (INNIO), MWM, Caterpillar (CAT), Rolls-Royce Power Systems (mtu), Cummins, Perkins, Mitsubishi Heavy Industries, Volvo penta, and GOOGOL Power.

Precision Control: Through extensive integration with globally renowned engines, Leelool's SCR denitrification system leverages high-precision sensors, proprietary electrical systems, and premium-grade components to ensure exact coordination. This guarantees NOx and NH₃ treatment efficiency in SCR/ASC systems meets stringent emission standards, with NOx reduction exceeding 96%. Automotive-grade urea dosing pumps maintain optimal urea consumption through closed-loop control. The system’s integrated CloudSync® communication module provides real-time emission analytics and seamlessly interfaces with plant DCS (Distributed Control Systems).