Skid-mounted SCR System

Model number:Skid-mounted

Leelool SCR system adopts selective catalytic reduction (SCR) technology, has the characteristics of low operating cost, convenient installation, safe operation, and online real-time monitoring.

▍Product Introduction

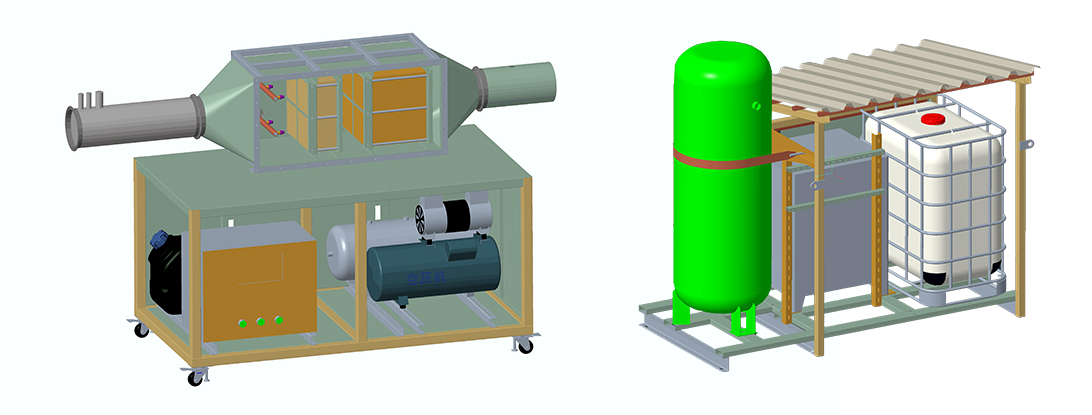

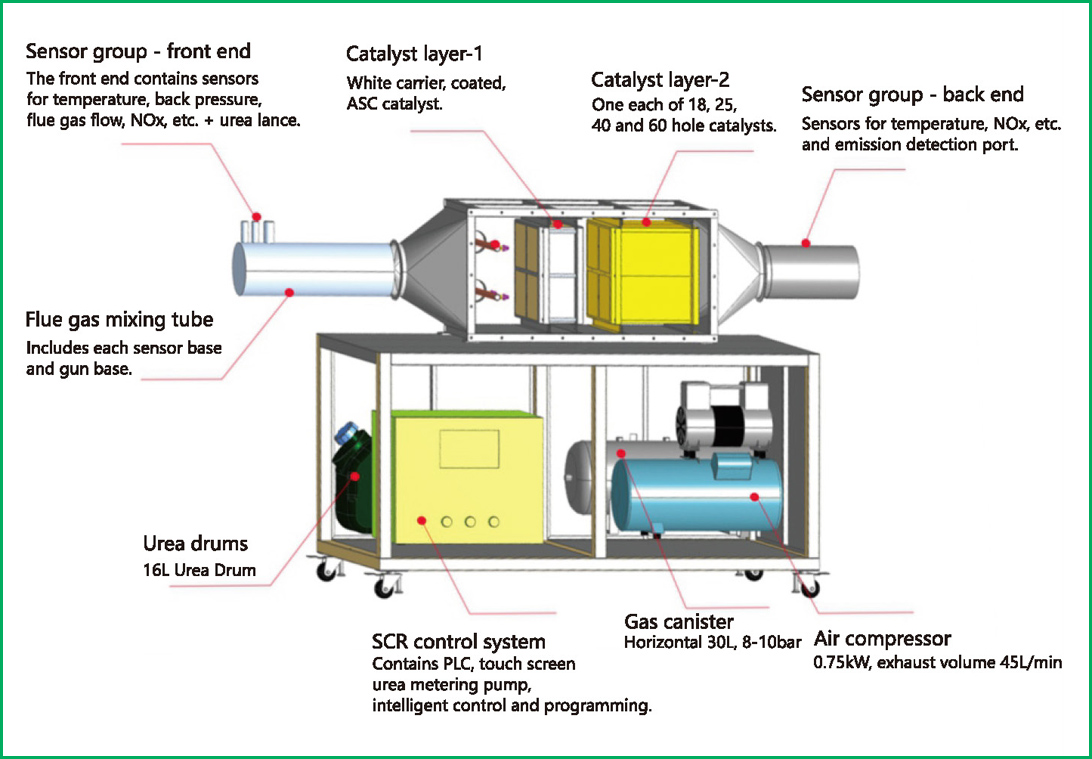

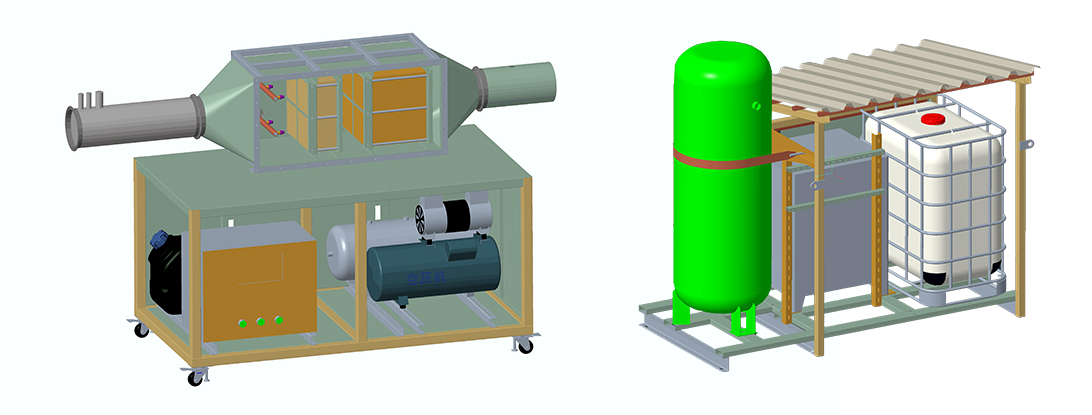

Leelool Skid-mounted SCR denitration system is an integrated and modular selective catalytic reduction denitration device. It integrates core components such as the reactor, catalyst, reducing agent injection system, fan, and control system into a steel skid, enabling factory prefabrication, overall transportation, and rapid installation. Its working principle involves injecting reducing agents such as ammonia water or urea into the flue gas under the action of the catalyst, reducing nitrogen oxides (NOx) to harmless nitrogen and water. The denitration efficiency can reach 80%-95%, making it suitable for flue gas purification scenarios such as boilers, kilns, and generator sets.

Compared to traditional on-site constructed denitration systems, skid-mounted systems offer advantages such as small footprint, short installation period (typically completed within 1-2 weeks), strong mobility (can be transferred to different working conditions as needed), and high automation level (one-click start/stop + remote monitoring). They are particularly suitable for retrofitting small and medium-sized boilers, emergency emission reduction, or temporary production needs. Currently, they are widely used in industries such as chemical, metallurgical, and building materials, serving as an efficient solution to meet ultra-low emission standards.

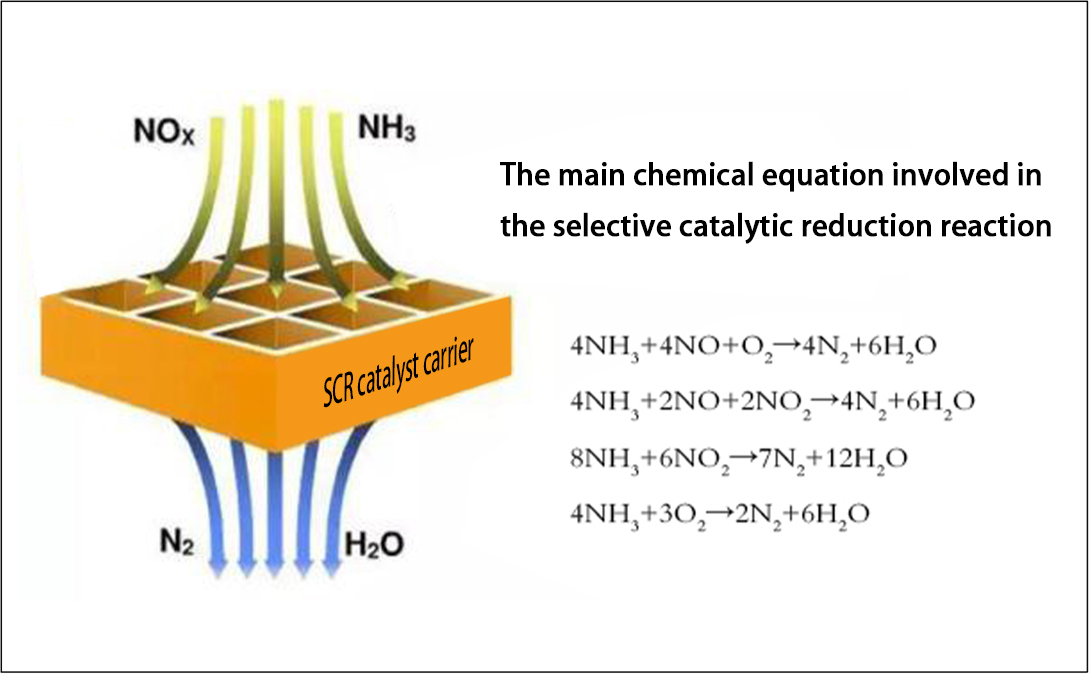

▍Introduction to SCR Technology

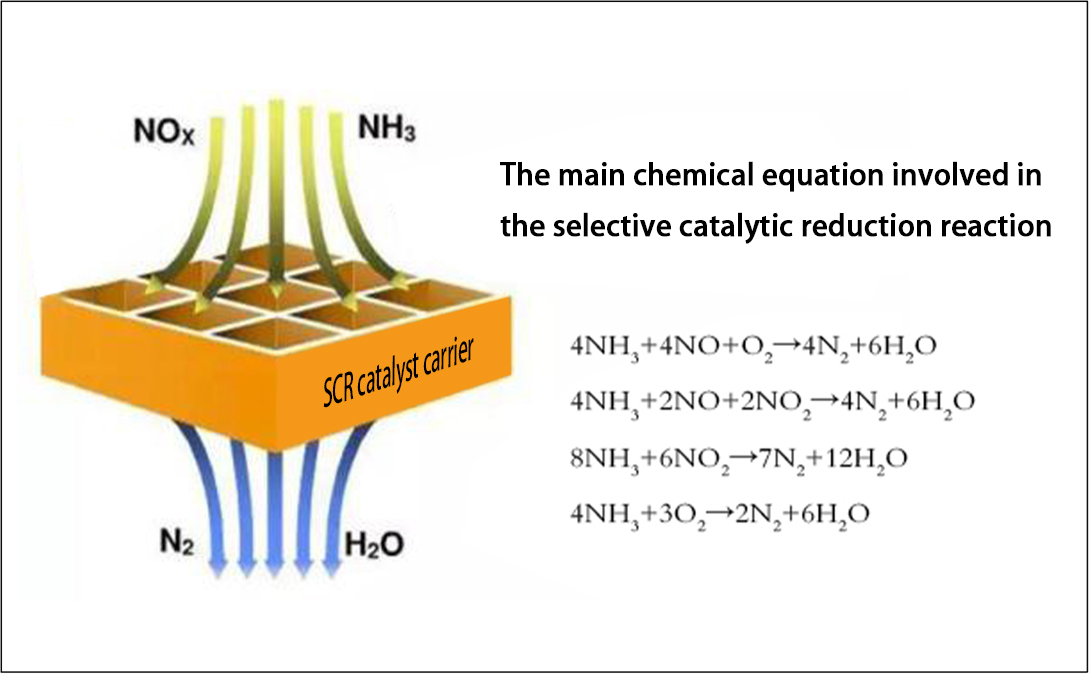

Selective Catalytic Reduction (SCR) method uses ammonia gas or a 32.5% urea solution as a reducing substance to control the concentration of nitrogen oxides in diesel engine exhaust. Under conditions where the oxygen concentration is more than two orders of magnitude higher than the nitrogen oxide concentration, under certain temperature and catalytic action, ammonia is used to reduce nitrogen oxides to nitrogen gas and water vapor. Since ammonia preferentially reduces nitrogen oxides and does not react with oxygen, it is called "selective catalytic reduction". For excess ammonia, a certain proportion of ammonia escape catalyst (ASC) can be coated at the end of the SCR reactor to ensure that ammonia reacts with oxygen to generate nitrogen and water vapor, avoiding secondary pollution caused by ammonia leakage.

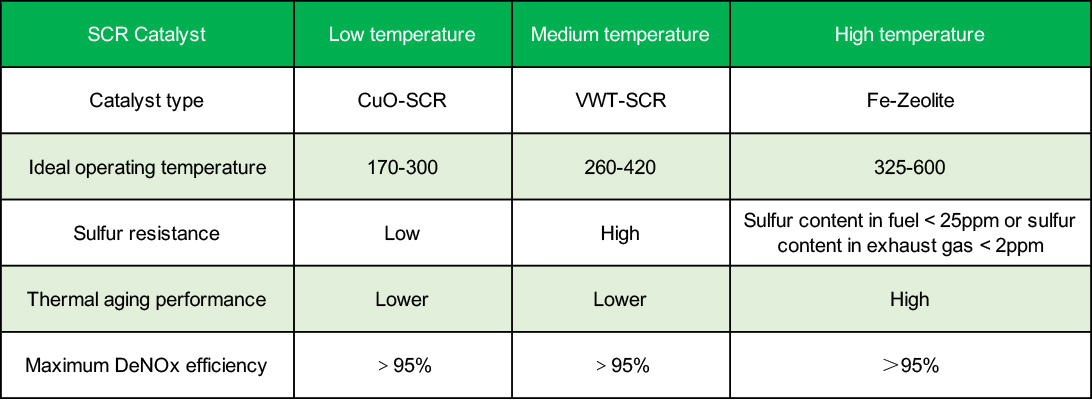

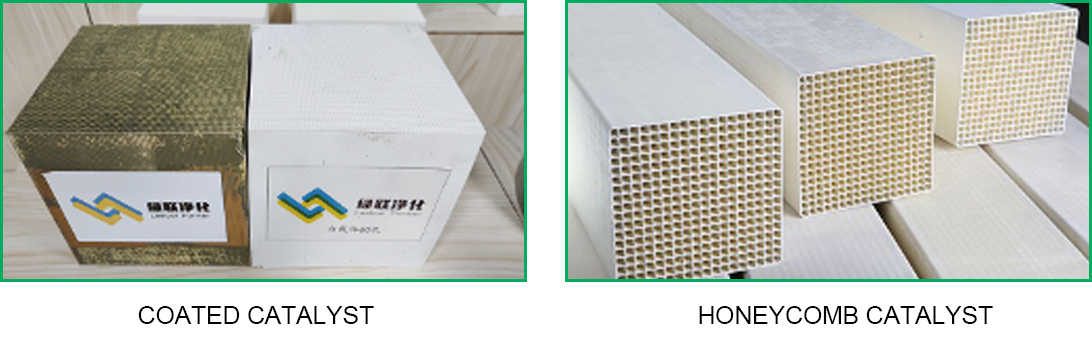

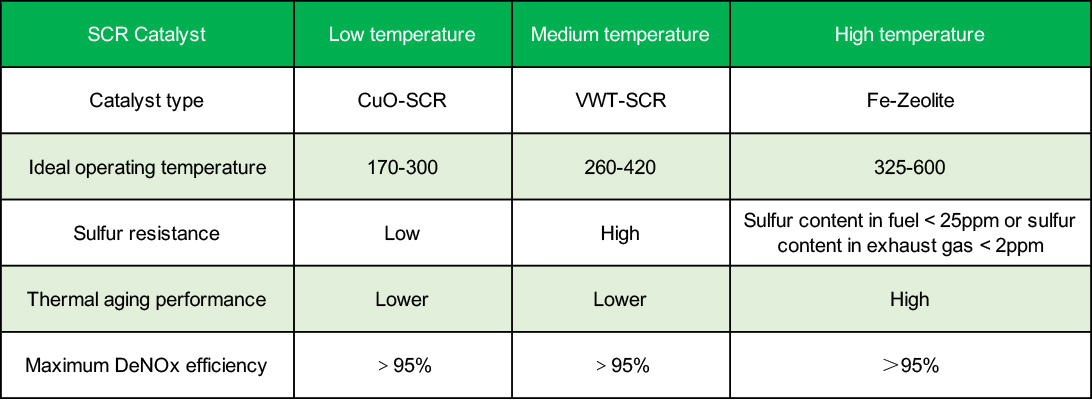

▍SCR Catalyst

▍Product Features

Skid installation design:The main components such as the mixing tube, control system, SCR reactor gas storage tank, air compressor, injection system, and urea tank are integrated onto a skid-mounted base for ease of transportation and installation. This design makes the system more compact, reduces the on-site installation process, and saves time and space

Easy to operate:All operational instruments and control devices of the skid-mounted SCR system are centralized on a single control console, allowing users to use it simply by connecting the electrical circuit and exhaust pipe, making operation convenient.

maintainable:With modular design, each component is relatively independent, and maintenance and repair can be carried out only for specific modules, reducing the complexity of maintenance.