The performances of a high-quality diesel engine exhaust purifier should be:

1.Low Startup Back Pressure

2.Strong Purification Capacity

3. Long Maintenance Cycle

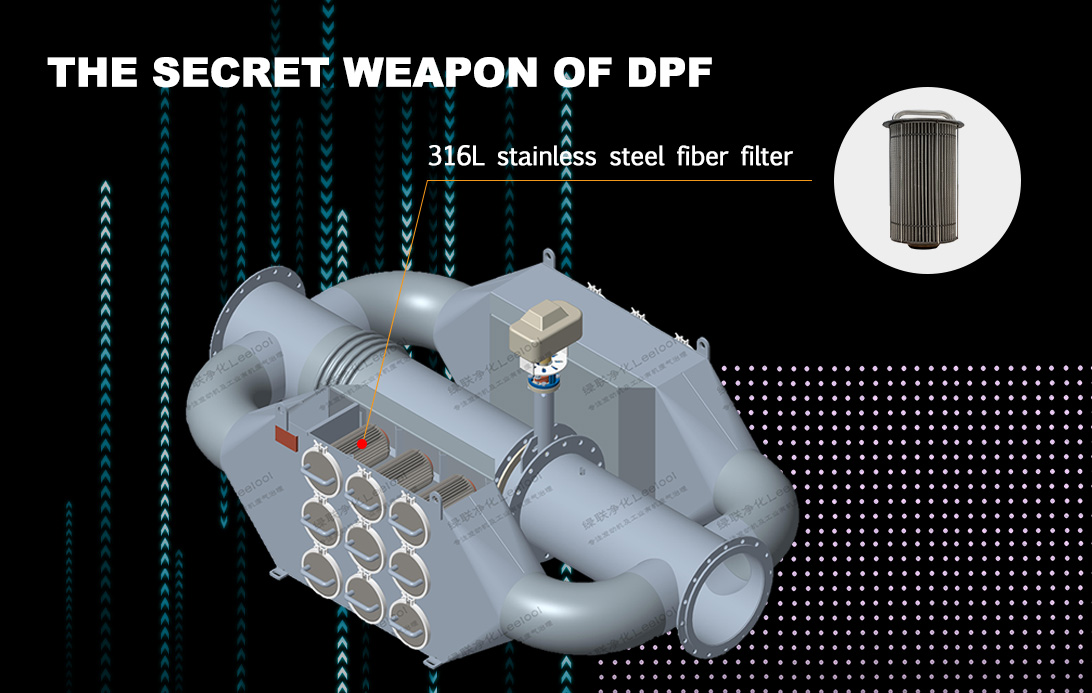

The core factor determining the purification capacity of the purifier includes:

1.The material of the filter element

2.The manufacturing process of the filter element

3.The effective filtration area of the filter element

1-minute guide you to know Leelool diesel engine Purifier filter element

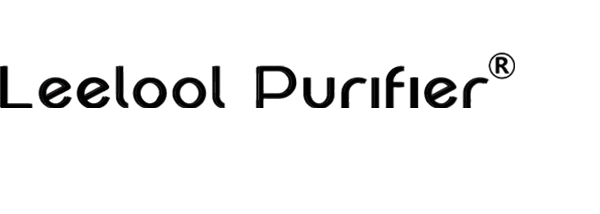

1. Filter Element Materials: Senior engineers of Leelool develop metal filter element with specific specifications based on the actual working scenario of engine exhaust. Through rigorous screening, 316L stainless steel fiber is used as the filter material.

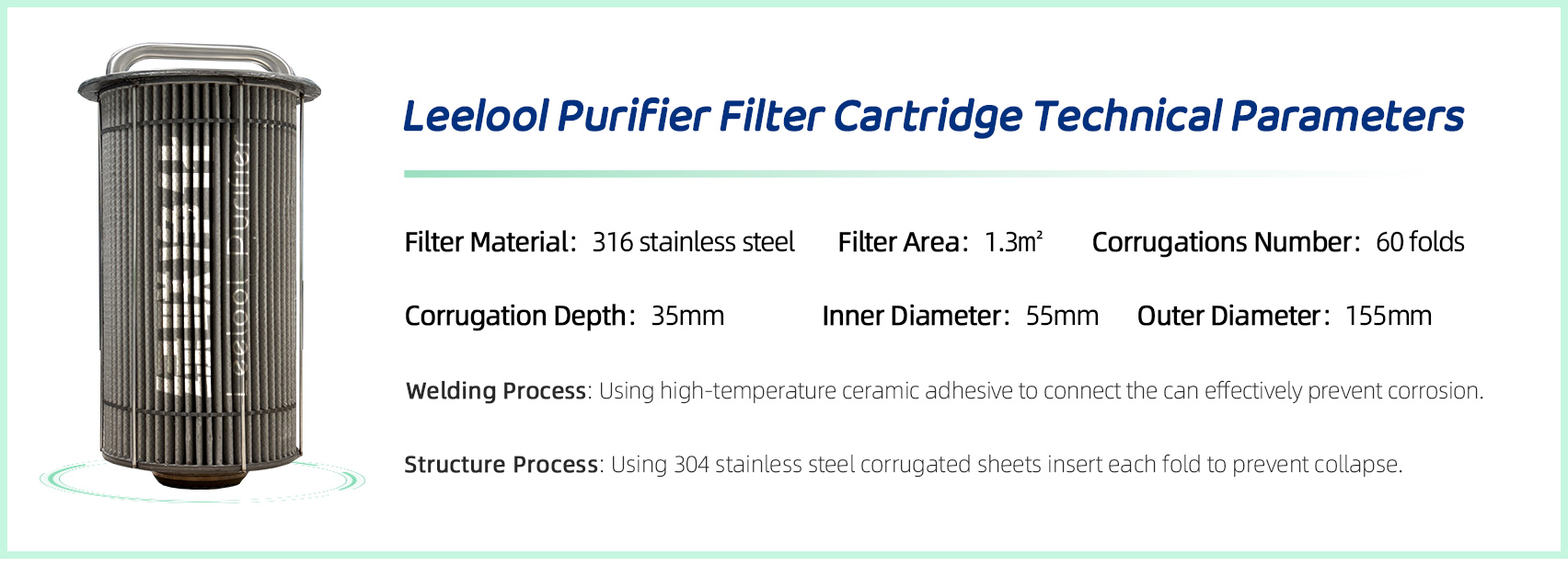

2. Structure process: Using a folded wave structure for production and manufacturing,304 stainless steel corrugated sheets are inserted in the middle of each crease.At the same time, stainless steel tie rods and anti collapse auxiliary reinforcement rings are added to connect both ends to ensure the stability of the filter structure.

3. Welding process: Using high-temperature ceramic adhesive to connect the cover plate and filter material,both ends of the filter material are embedded with 1mm,these steps can effectively prevent corrosion and extends the service life of the filter element.

Technical parameters of Leelool purifier filter element

Filter Material:316L Stainless Steel

Processing Technique:Folding Process

Folds No.:≥60 times

Folds Depth:35mm

Filtration Area:1.3m²

Welding Material:High-temperature Ceramic Glue

Leelool Purifiction ensures rigorous screening of filter material ,at the same time based on long-term project practice experience and continuous iteration of filter production and manufacturing processes, ensures that the treatment effect of every filter reaches:

1.Low Startup Back Pressure

2.Strong Purification Capacity

3.Long Maintenance Cycle

4.Low maintenance required

5.Enhanced durability and longevity

6.Low-altitue emissions compliance