▍Filter Cartridge Introduction

Phone: +86-0769-22899111

Mobile phone: +86-18925574911

Email: market@leelool.com

Fax: +86-0769-22899811

Company Address: Room 102, Building l, No. 7Hsinchu Road, songshan Lake Park, DongguanCity, Guangdong Province

Factory Address: Room 102, No, 12 shajingkengRoad, Fushan village, Liaobu Town, DongguanCity,Guangdong Province

▍Product Introduction

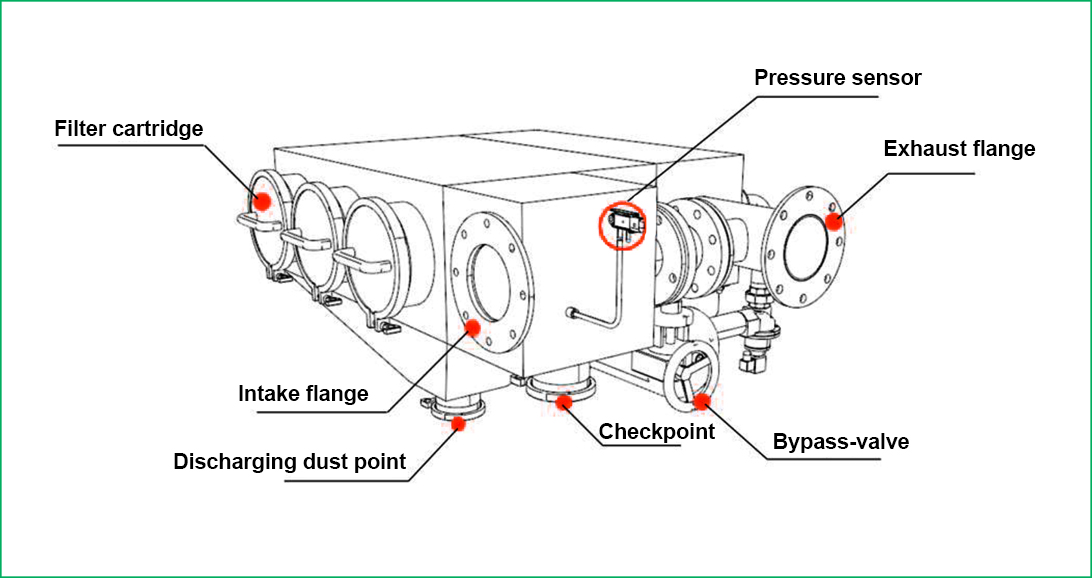

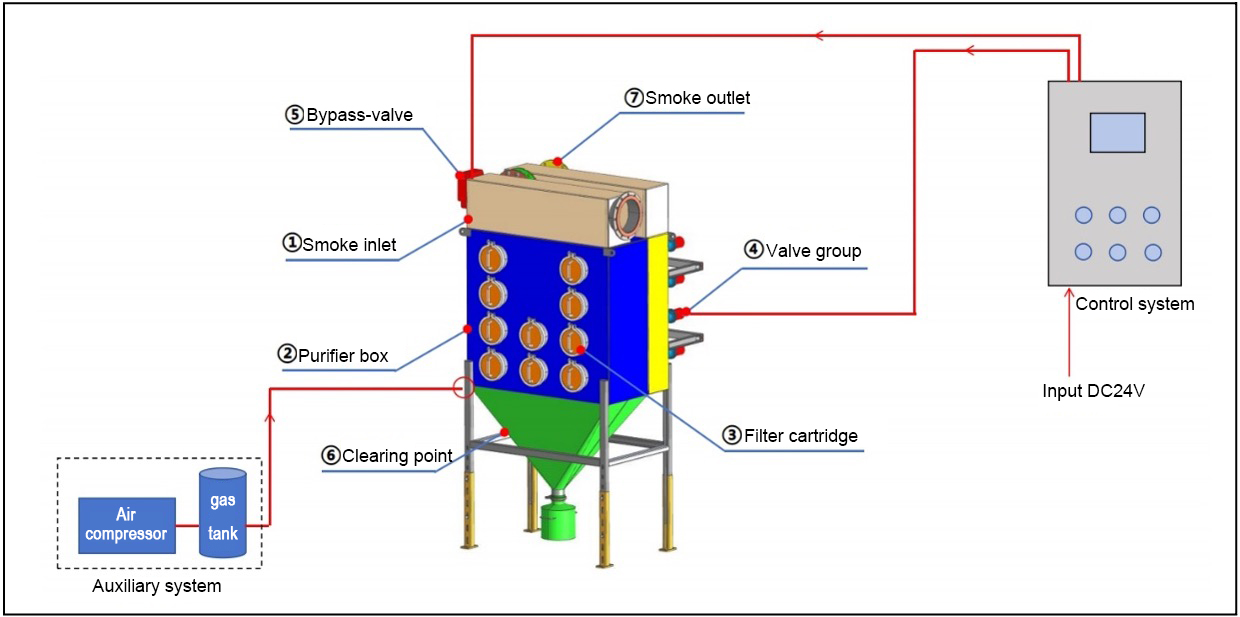

The maintenance-free black smoke purifier is an independently developed product for treating black smoke in diesel engines under continuous operation conditions, based on the third-generation alloy metal black smoke purifier. Its main structure includes an air storage tank, a back-blow valve, a folding fan-type metal filter element, an oil-gas separator (optional), an ash discharge chamber, a safety bypass system, and an electrical control system, etc. It can effectively control the emission of carbon particles in the exhaust gas of the main operating diesel engines with unstable working conditions.

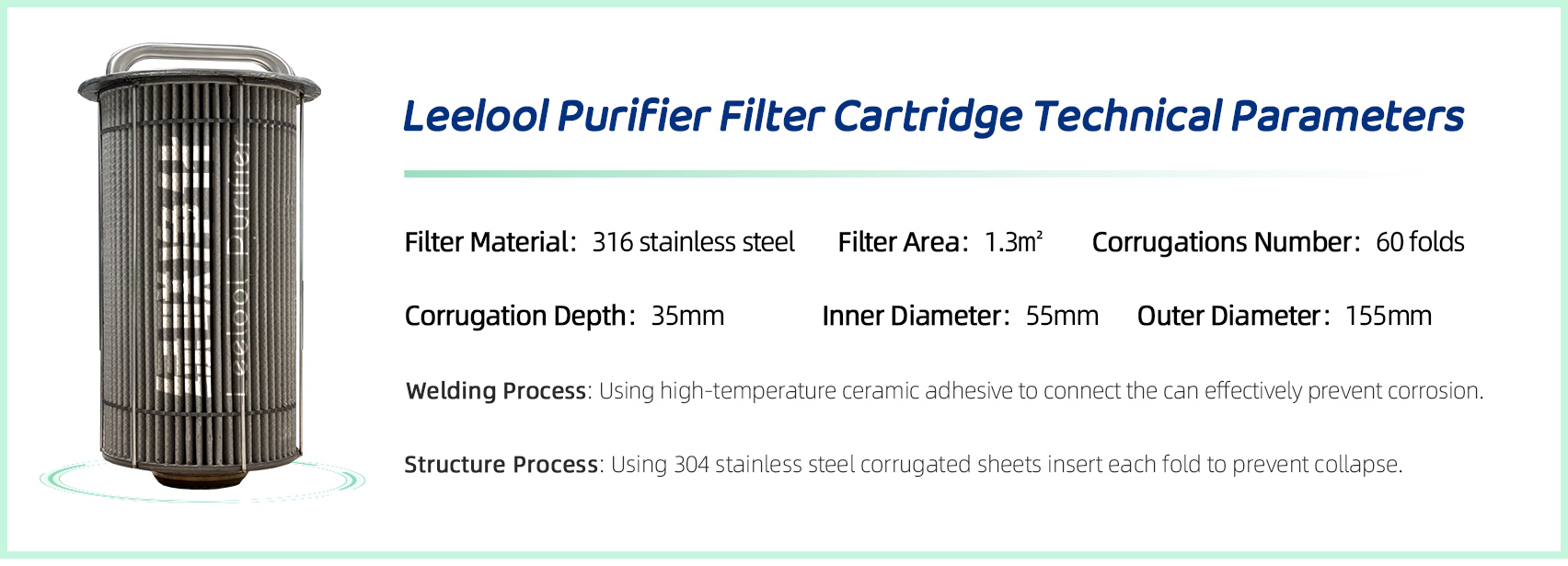

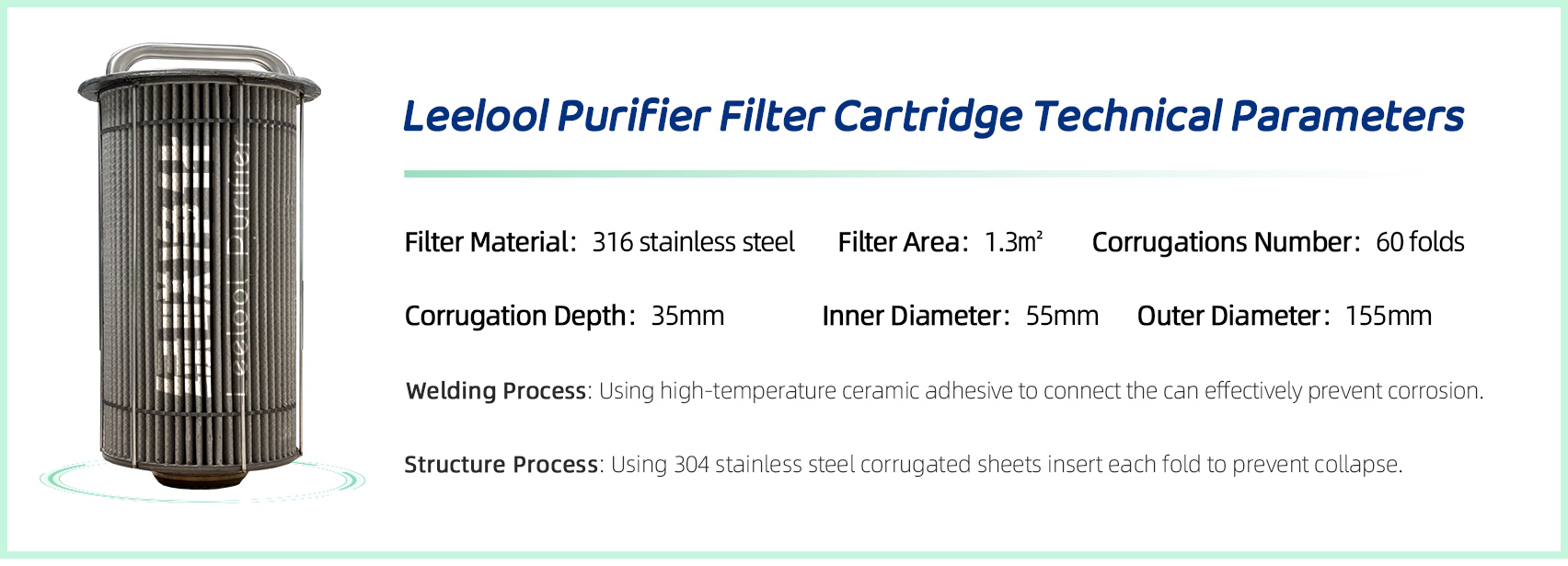

▍Filter Cartridge Introduction

▍Working Principle

After the exhaust gas of the diesel engine enters the purification chamber through the air intake chamber, it passes through each filter element at 360 degrees. The dense stainless steel filter screen can intercept 90% of the black smoke particles, which are evenly attached to the surface of each filter element. The cleaned exhaust gas enters the next section of the box and is discharged.

There is a high-pressure gas nozzle at the center of each filter element, which is connected to a back-blow solenoid valve. The rear end is connected to a compressed air storage tank and an air compressor. It can be set to inject high-pressure gas once with the help of external compressed air at fixed intervals (adjustable according to the actual working conditions of the diesel engine, such as 30S, 60S, 90S, etc.), so as to blow off the black smoke particles attached to the outer surface of each filter element to the bottom of the box, and the particles are collected in the ash accumulation chamber at the bottom. Users only need to open the cover plate of the bottom ash accumulation chamber and clean the accumulated ash regularly.

The air intake chamber of the purifier is also equipped with a pressure sensor, and the purifier is equipped with a bypass pressure relief valve. When the back pressure is too high, it will automatically alarm, and the bypass valve will automatically open for emergency pressure relief to protect the safe operation of the engine.

▍Back-blow System

The back-blow system is mainly composed of an air compressor, an air storage tank, a back-blow solenoid valve, and a control system. The back-blow interval is set according to the concentration of black smoke particles in the engine exhaust. The back-blow solenoid valve opens instantly to provide back-blow air pressure (far greater than the engine exhaust pressure), which instantly blows off the particles accumulated on the surface of the filter element from the filter layer of the filter element and makes them fall into the ash accumulation chamber at the bottom plate of the box. The back-blow pressure control, time control, and the structure and angle of the back-blow nozzle are the core of the back-blow system.