Provide you with free analysis of the air pollution emission standards of the project site, and provide targeted product selection and programme design, product knowledge training to help you solve the project pain points and difficulties.

500+ sets of product installation and operation service experience, more than 500MW+ internal combustion generating unit black smoke or NOx treatment experience at home and abroad.

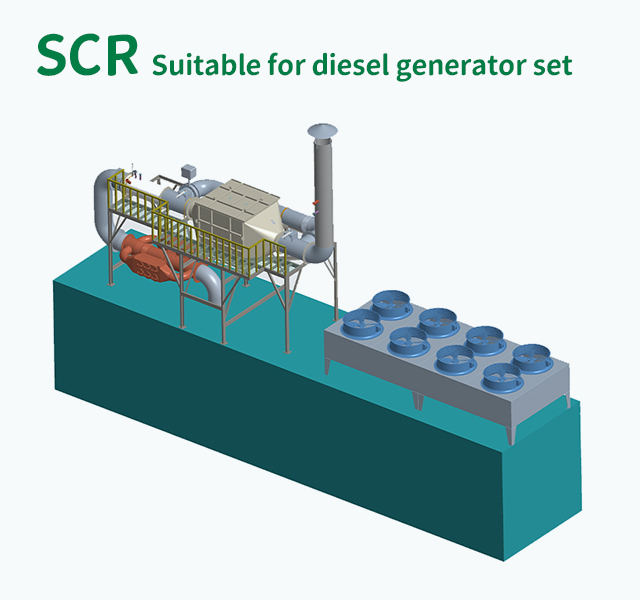

Uniquely designed electrical system with high-precision sensors and other electronic components to achieve precise coordination, NOx (nitrogen oxides) control efficiency of more than 95%.

Over 28 years of experience in the generatorindustry

Accumulated installed power exceeding 4000MW

A professional technical team of over 40 people

Leelool Purification Technology (Dongguan) Co., Ltd. is located in Songshan Lake High tech Industrial Park, Dongguan, Guangdong Province. It is a high-tech environmental protection enterprise initiated by domestic researchers and manufacturers in the fields of engines and generator sets, and shares key technologies with a team of scientists from Europe and America who have been engaged in catalyst and air pollutant control research for more than 20 years, as well as well-known domestic research institutions.

The Leelool production base is located at No. 12 Shajingkeng Road, Liaobu Town, Dongguan CityGuangdong Province. lt is responsible for producing and assembling the Leelool generator set ex.haust purification series products. Leelool has successfully passed the ISO system certification.The complete production equipment and rigorous testing process ensure the stable productivity ofGreen Union Purification.

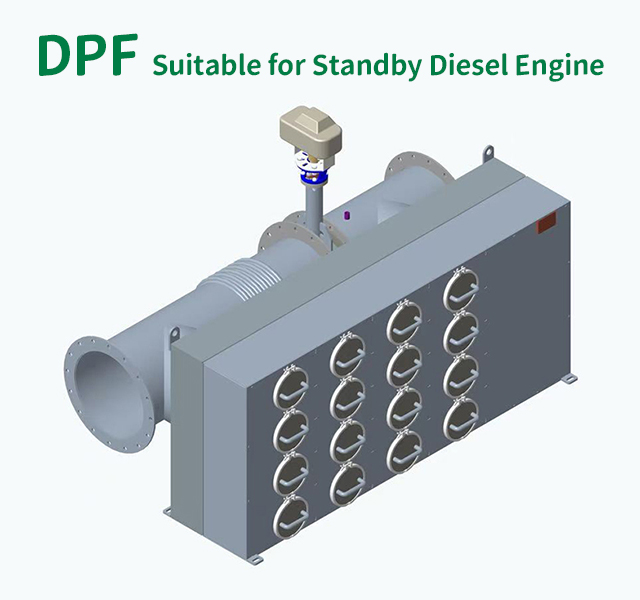

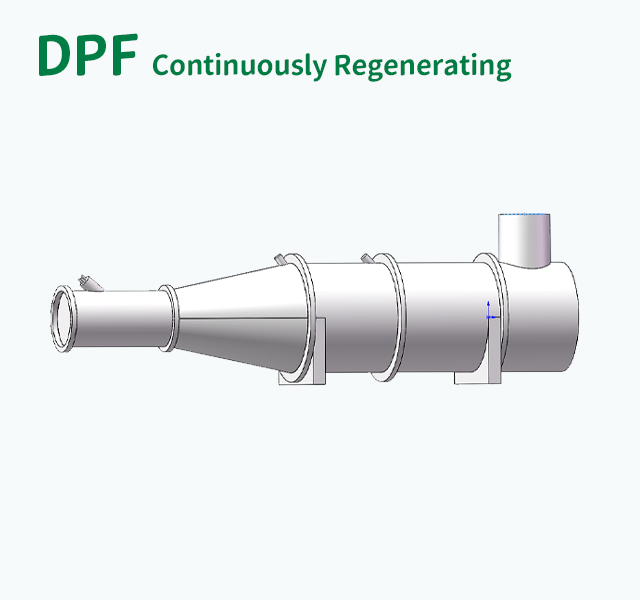

It consists of a box, several filter elements, a smoke exhaust pipe, a bypass valve, a controller, etc. It can handle diesel engine exhaust emissions ranging from 10L to 110L.

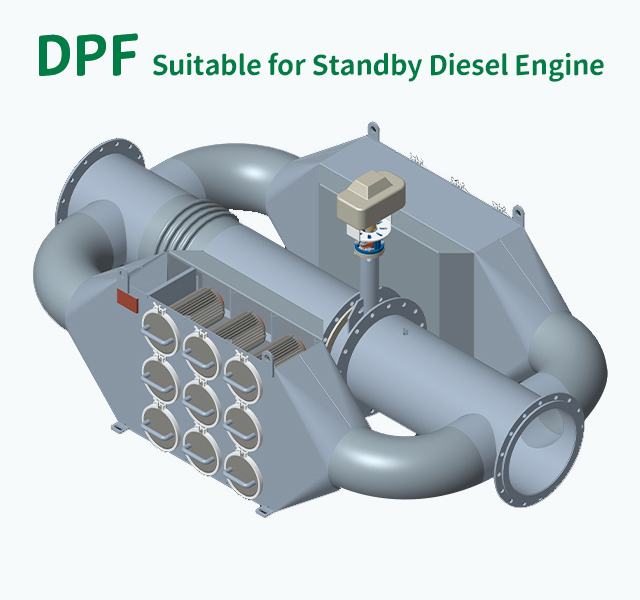

It consists of 2 boxes, several filter elements, a smoke exhaust pipe, a bypass valve, a controller, etc. It can handle diesel engine exhaust emissions ranging from 50L to 110L.

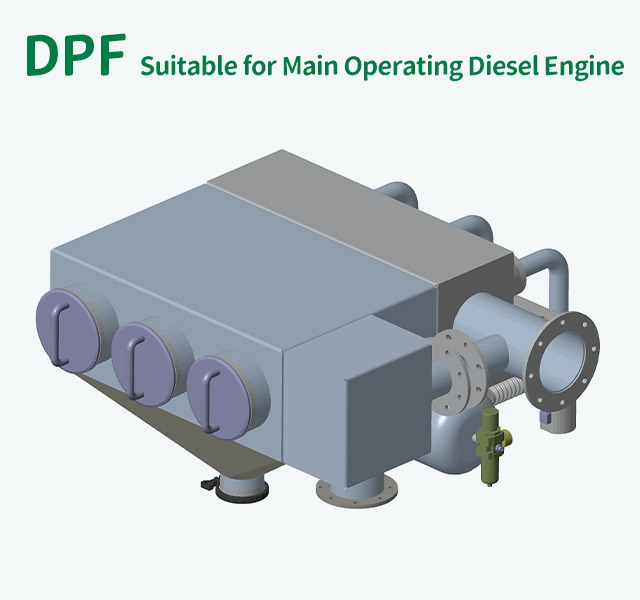

It can effectively control the emission of carbon particles in the exhaust gas of the main operating diesel engines with unstable working conditions.

It continuously traps and automatically regenerates exhaust particulate matter, without increasing the back pressure of the exhaust system or affecting engine power.

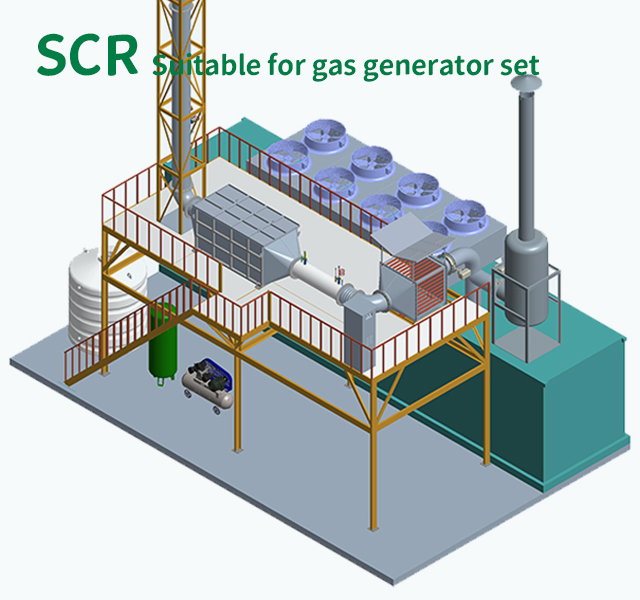

Leelool SCR system adopts selective catalytic reduction (SCR) technology, has the characteristics of low operating cost, convenient installation, safe operation, and online real-time monitoring.

Leelool SCR system adopts selective catalytic reduction (SCR) technology, has the characteristics of low operating cost, convenient installation, safe operation, and online real-time monitoring.

Leelool SCR system adopts selective catalytic reduction (SCR) technology, has the characteristics of low operating cost, convenient installation, safe operation, and online real-time monitoring.

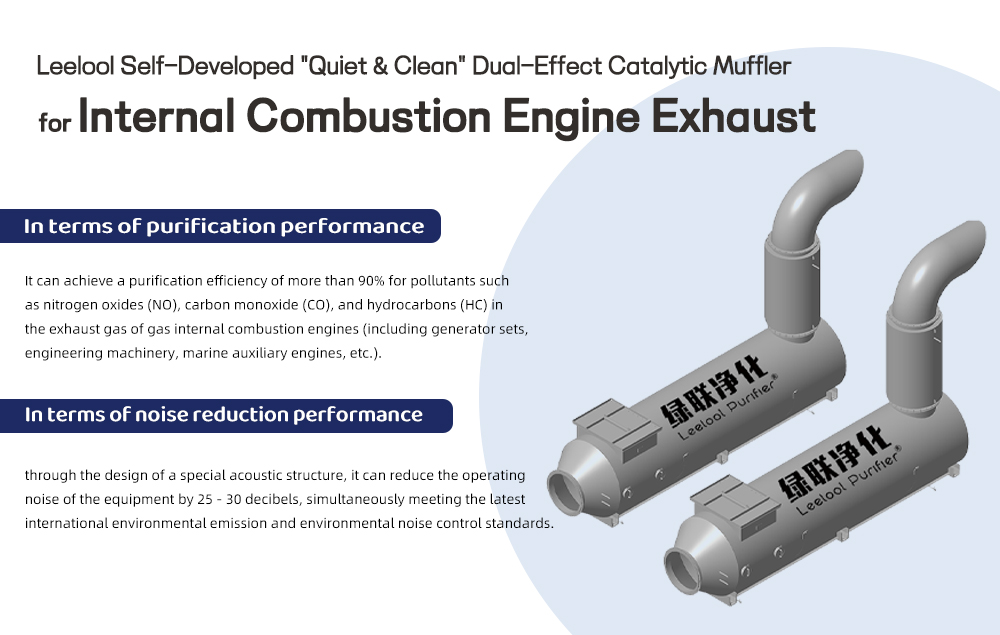

The pioneering integrated design of "high-efficiency catalytic purification + high-decibel noise reduction" successfully breaks through the technical bottleneck of traditional equipment with limited functionality.

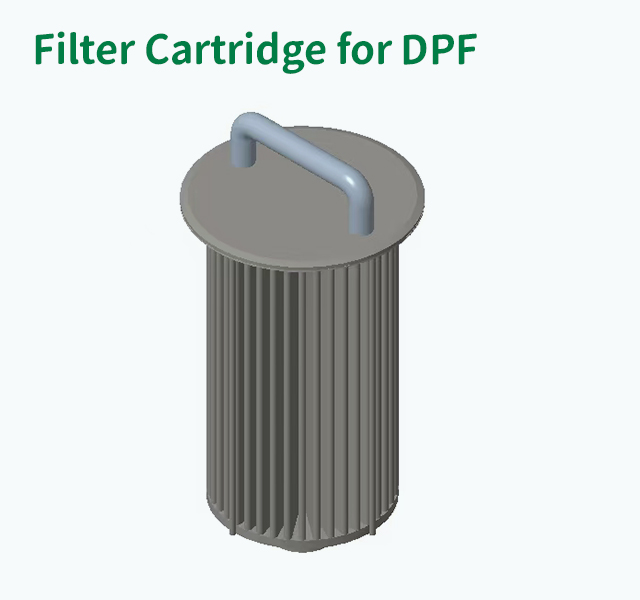

Leelool Purification ensures that the treatment effect of every DPF meets the standard by strictly screening filter material, leveraging long-term project practical experience, and continuously iterating the production of filters.

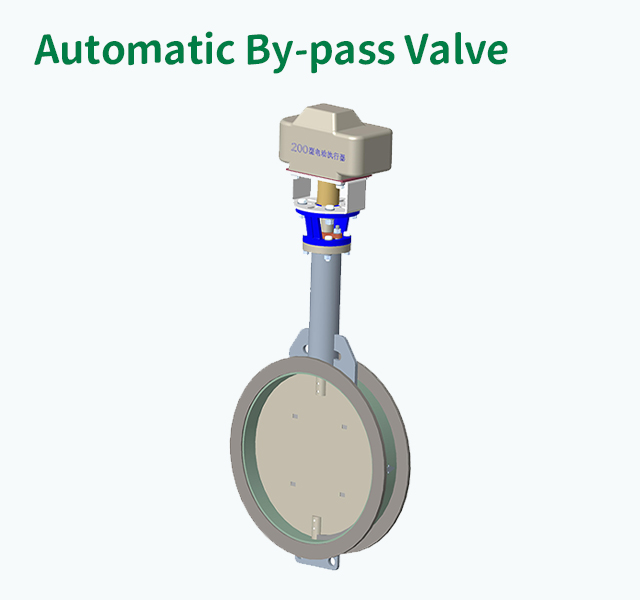

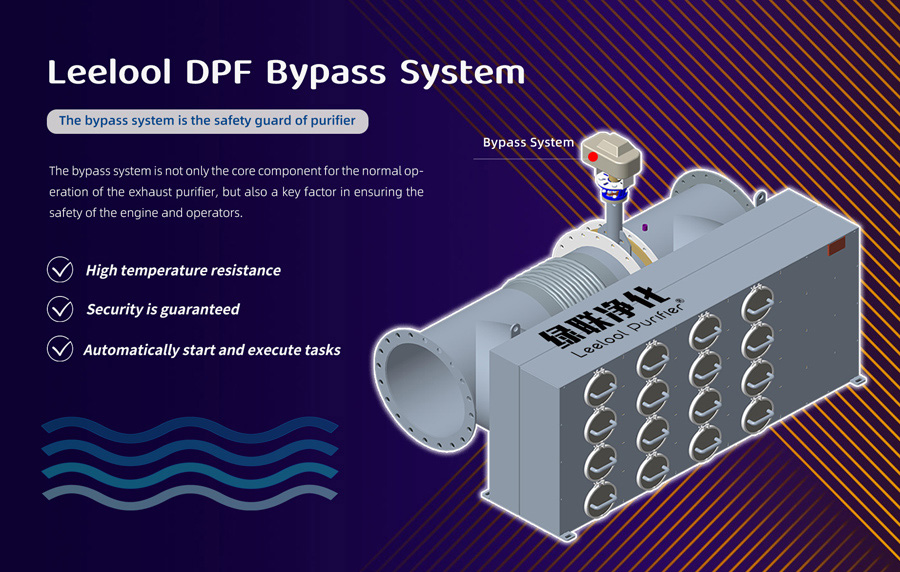

The bypass system is not only the core component for the normal operation of the exhaust purifier,but also a key factor in ensuring the safe operation of the engine and the personal safety of the operators.

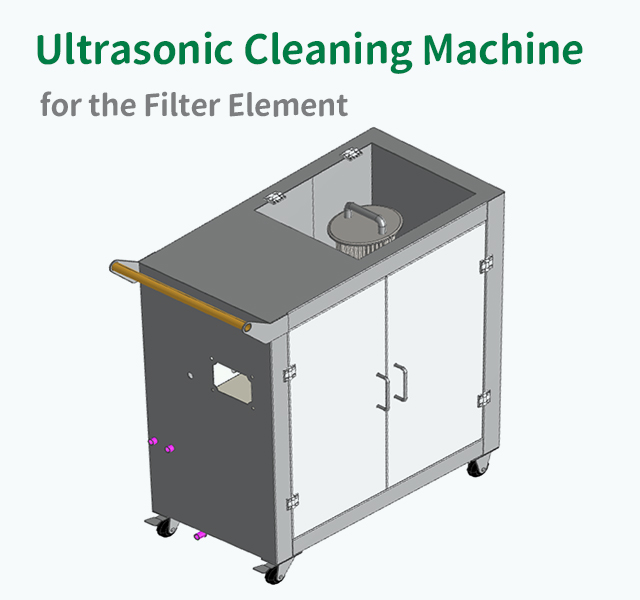

It integrates two core functions: high-speed cleaning and dehydration, which can quickly complete the cleaning task of the filter, greatly reducing the burden on personnel and achieving an intelligent cleaning process.

It can accurately diagnose temperature and pressure anomalies based on inlet temperature, outlet temperature, and back pressure, and control the opening or closing of bypass valves.

We Awarded 3invention patents, 20 utilitymodelpatents, 11 desiqn patents..

This device is tailor-developed exclusively for the dedicated test bench scenario of diesel engines used in a large domestic diesel generator set we supply. It focuses on addressing the pollutant treatment needs during the testing process: it not only achieves efficient, reliable, and precise treatment of over-sprayed diesel, black smoke, and nitrogen oxides, but also ensures the test bench operates continuously and stably without any interference throughout the entire process.

Read More >

Recently, the first batch of Leelool Purification’s new-generation "Quiet & Clean" dual-effect catalytic mufflers for internal combustion engine exhaust – a product embodying technological innovation and environmental protection responsibility – has successfully rolled off the production line.

Read More >

In DPF, the bypass system plays a role in opening or closing the bypass pipeline to control the flow of exhaust gas.When DPF is working normally, the bypass system is closed and the engine exhaust is purified by the purifier before being discharged.After the DPF completes the exhaust treatment during startup, the bypass system opens and the engine exhaust is directly discharged through the bypass pipe.

Read More >